20

2024

-

08

Some thoughts on intelligent manufacturing

Currently, an industrial revolution characterized by the convergence of new generation information and communication technologies with manufacturing is emerging globally, and intelligent manufacturing has become the primary direction for the development of the manufacturing industry.

Editor's Note: Currently, an industrial revolution characterized by the integration and development of new generation information and communication technologies and manufacturing is emerging globally, and intelligent manufacturing has become the primary direction for manufacturing development. Intelligent manufacturing is still in the process of continuous development, and the understanding of it varies among different sectors of society. The Mechanical Industry Instrument and Meter Comprehensive Technology and Economics Research Institute has long tracked the development of world manufacturing technology and, based on extensive corporate surveys and international exchanges, has formed the article "Some Understandings of Intelligent Manufacturing," which we share with you.

Some Understandings of Intelligent Manufacturing

Mechanical Industry Instrument and Meter Comprehensive Technology and Economics Research Institute

1. Concept of Intelligent Manufacturing

"Intelligent manufacturing" can be interpreted from two aspects: manufacturing and intelligence. First, manufacturing refers to the process of processing or reprocessing raw materials and assembling components. Generally, manufacturing is divided into process manufacturing and discrete manufacturing, depending on the continuity of the production method. According to the current Chinese standard GB/T4754-2002, China's manufacturing industry includes 31 industries, further divided into approximately 175 medium categories and 530 small categories, covering all aspects of the national economy.

Intelligence is composed of two words: "wisdom" and "ability." The process from sensation to memory to thinking is called "wisdom." The result of wisdom produces behavior and language, and the process of expressing behavior and language is called "ability." The two together are called "intelligence (intelligent/smart)." Therefore, the entire process of sensation, memory, recall, thinking, language, and behavior is called the intelligent process, which is the manifestation of wisdom and ability.

At present, there is no accurate definition of intelligent manufacturing internationally or domestically, but the recently released "Intelligent Manufacturing Development Plan (2016-2020)" provides a relatively comprehensive descriptive definition: Intelligent manufacturing is a new type of production method based on the deep integration of new generation information and communication technologies and advanced manufacturing technologies, running through all aspects of manufacturing activities such as design, production, management, and service, and possessing functions such as self-perception, self-learning, self-decision-making, self-execution, and self-adaptation. Promoting intelligent manufacturing can effectively shorten product development cycles, improve production efficiency and product quality, reduce operating costs and resource and energy consumption, and promote the development of new industries and models such as Internet-based crowdsourcing, crowdsourcing, and crowdfunding. Intelligent manufacturing is characterized by intelligent factories as carriers, intelligent key manufacturing links as the core, end-to-end data flow as the basis, and network interconnection as support. This actually points out the core technologies, management requirements, main functions, and economic goals of intelligent manufacturing, reflecting the important role of intelligent manufacturing in China's industrial transformation and upgrading and the sustained development of the national economy.

However, due to China's weak and unbalanced technological foundation, enterprises are often at a loss as to where to start when implementing and upgrading intelligent manufacturing. Therefore, based on the descriptive definition of intelligent manufacturing, the following will present preliminary understandings of four aspects: intelligent factories, intelligent manufacturing links, network interoperability, and end-to-end data flow, in order to illustrate the main content of intelligent manufacturing.

2. What is an Intelligent Factory?

An intelligent factory is the carrier for realizing intelligent manufacturing. In an intelligent factory, intelligent, networked, distributed management is achieved through the integration and interoperability of production management systems, computer-aided tools, and intelligent equipment, thereby achieving the coordination of enterprise business processes and technological processes, and the dynamic allocation of production resources (materials, energy, etc.) within and between enterprises.

On the one hand, "A workman who wants to do his work well must first sharpen his tools." The sharp tools for realizing intelligent manufacturing are digital and networked software and manufacturing equipment, including the following types:

1) Computer-aided tools, such as CAD (Computer-Aided Design), CAE (Computer-Aided Engineering), CAPP (Computer-Aided Process Planning), CAM (Computer-Aided Manufacturing), etc.;

2) Computer simulation tools, such as logistics simulation, engineering physics simulation (including structural analysis, acoustic analysis, fluid analysis, thermodynamic analysis, motion analysis, composite material analysis, etc., multi-physical field simulation), process simulation, etc.;

3) Factory/workshop business and production management systems, such as ERP (Enterprise Resource Planning), MES (Manufacturing Execution System), PLM (Product Lifecycle Management)/PDM (Product Data Management), etc.;

4) Intelligent equipment, such as high-end CNC machine tools and robots, additive manufacturing equipment (3D printers), intelligent sensing and control equipment, intelligent inspection and assembly equipment, intelligent logistics and warehousing equipment, etc.;

5) New generation information technologies, such as the Internet of Things, cloud computing, and big data.

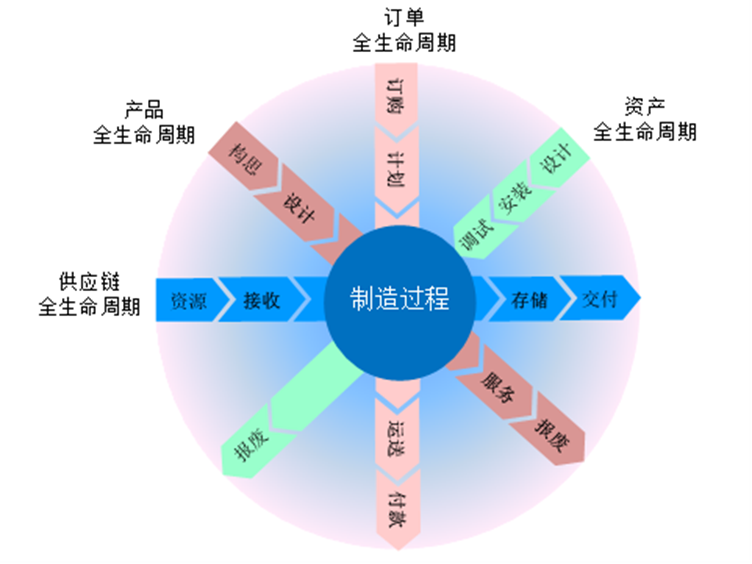

On the other hand, intelligent manufacturing is a "super" system engineering covering a wider range of fields and technologies. In the production process, it takes product lifecycle management as the main line, and is also accompanied by supply chain, order, and asset lifecycle management, as shown in Figure 1.

Figure 1: Intelligent Manufacturing Lifecycle Management

In an intelligent factory, with the help of various production management tools/software/systems and intelligent equipment, various links from design and production to sales and maintenance are connected, realizing intelligent production such as product simulation design, automatic production scheduling, information uploading and issuing, production process monitoring, online quality monitoring, and automatic material distribution. Several "intelligent" production scenarios in intelligent factories are introduced below.

Scenario 1: Design/Manufacturing Integration. In the aerospace manufacturing field with better intelligence, Model-Based Definition (MBD) technology is used to realize product development, using an integrated three-dimensional solid model to completely express the design and manufacturing information of the product (product structure, three-dimensional dimensions, BOM, etc.). All production processes, including product design, process design, tooling design, product manufacturing, and inspection and testing, are based on this model, which breaks down the barriers between design and manufacturing and effectively solves the problem of consistency between product design and manufacturing.

Scenario 2: Supply Chain and Inventory Management. The types and quantities of products that enterprises need to produce are confirmed through orders, making production precise. For example: using ERP or WMS (Warehouse Management System) for raw material inventory management, including various raw materials and supplier information. When a customer order is placed, ERP automatically calculates the required raw materials and, based on supplier information, promptly calculates the procurement time of raw materials, ensuring the lowest possible inventory cost, even zero, while meeting delivery times.

Scenario 3: Quality Control. Sensors, equipment, and instruments used in the workshop can automatically collect key data required for quality control online; the production management system provides online quality monitoring and early warning methods such as quality anomaly judgment and process stability judgment based on real-time collected data, timely and effectively discovering product quality problems. In addition, products have unique identifiers (barcodes, QR codes, electronic tags) and can trace data related to product quality in text, images, and videos, such as material batches, suppliers, operators, operating locations, processing technology, processing equipment information, operating time, quality inspection and judgment, and defect handling processes.

Scenario 4: Energy Efficiency Optimization. Collect energy efficiency-related data from key manufacturing equipment, production processes, and energy supply links, and use MES systems or EMS (Energy Management Systems) to manage and analyze energy efficiency-related data, timely discovering fluctuations and anomalies in energy efficiency, and making corresponding adjustments to production processes, equipment, energy supply, and personnel under the premise of ensuring normal production, achieving improved production process energy efficiency.

In short, the establishment of a smart factory can significantly improve working conditions, reduce manual intervention on the production line, and enhance the controllability of the production process. Most importantly, it leverages information technology to integrate various business processes, achieving interconnectivity from design and production to sales. Based on this, it optimizes and improves resource allocation, further enhancing production efficiency and product quality.

3. How to achieve intelligent manufacturing processes

The prevalence of internet technology has made real-time communication between enterprises and individual customers a reality, enabling the manufacturing industry to achieve demand-driven production from the demand side to the R&D and production side, and a transformation from "manufacturing" to "service" industries. Therefore, enterprises must lead their competitors in completing the digital, networked, and intelligent transformation and upgrading, achieving mass customization to meet personalized needs and provide intelligent services in order to remain competitive in the ever-changing market.

Visible are personalized customization and intelligent services; invisible are the digitalization, networking, and intelligence of various stages of production and manufacturing. To achieve intelligent manufacturing, networking is the foundation, digitalization is the tool, and intelligence is the goal.

Networking refers to using the same or different networks to connect various computer systems, intelligent equipment, and even operators, materials, semi-finished products, and finished products in a factory/workshop to achieve information exchange and good interaction between equipment and equipment, equipment and people, and materials and equipment. The intelligent equipment on the production site is connected through an industrial control network, which includes fieldbuses (such as PROFIBUS, CC-Link, Modbus, etc.), industrial Ethernet (such as PROFINET, CC-LinkIE, Ethernet/IP, EtherCAT, POWERLINK, EPA, etc.), and industrial wireless networks (such as WIA-PA, WIA-FA, WirelessHART, ISA100.11a, etc.). Radio Frequency Identification (RFID) technology also plays an important role in smart factories, enabling automatic identification and tracking management of products throughout the manufacturing process. The production management system of the workshop/factory directly uses

Ethernet connection. In addition, the factory network also requires connection to the internet to achieve value chain enterprise collaborative manufacturing, remote product diagnosis and maintenance, and other intelligent services through big data applications and industrial cloud services.

Digitalization refers to using various computer tools to, on the one hand, conduct auxiliary design and simulation verification of product object characteristics, production processes, and even factory layouts in a virtual environment. For example: using CAD (Computer-Aided Design) to perform two-dimensional and three-dimensional product design and generate NC program G-code; using CAE (Computer-Aided Engineering) to analyze and verify the performance and safety and reliability of engineering and products; using CAPP (Computer-Aided Process Planning) to formulate and simulate the mechanical processing process of parts through numerical calculation, logical judgment, and reasoning; and using CAM (Computer-Aided Manufacturing) for production equipment management control and operation processes; and on the other hand, to digitally manage the production process. For example: using CDD (Common Data Dictionary) to establish a product lifecycle data integration and sharing platform; using PDM to manage product-related information (including parts, structures, configurations, documents, CAD files, etc.); and using PLM for product lifecycle management (a series of application solutions for the creation, management, distribution, and application of information throughout the product lifecycle).

Intelligence can be divided into two stages. The current stage is oriented towards customized design and supports a multi-variety, small-batch production model. By using intelligent production management systems and intelligent equipment, intelligent management of the entire product lifecycle is achieved. The future vision is to achieve self-organizing production with self-sensing, real-time analysis, autonomous decision-making, self-configuration, and precise execution. This requires, firstly, the realization of transparent management of production data, where data generated from various manufacturing stages can be monitored and analyzed in real-time to make intelligent decisions; secondly, it requires the production line to have high flexibility and be able to be modularly combined to meet the needs of producing different products. In addition, the intelligence of the product itself should be improved, such as providing user-friendly human-computer interaction, speech recognition, data analysis, and other intelligent functions. Each product and component in the production process is identifiable and traceable, and the product even understands the details of its manufacturing and how it will be used.

Digitalization, networking, and intelligence are effective means of ensuring that intelligent manufacturing achieves the economic goals of "two improvements and three reductions." Digitalization ensures consistency of products from design to manufacturing and performs simulation verification of product structure, function, performance, and even production processes before sampling, greatly saving development costs and shortening development cycles. Networking achieves dynamic allocation of various resources in research, design, production, and sales through horizontal and vertical information integration, as well as full product tracking and testing, achieving personalized customization and flexible production while improving product quality. Intelligence integrates artificial intelligence into the entire product lifecycle, including design, perception, decision-making, execution, and service, improving production efficiency and product core competitiveness.

4. How to achieve network interconnectivity

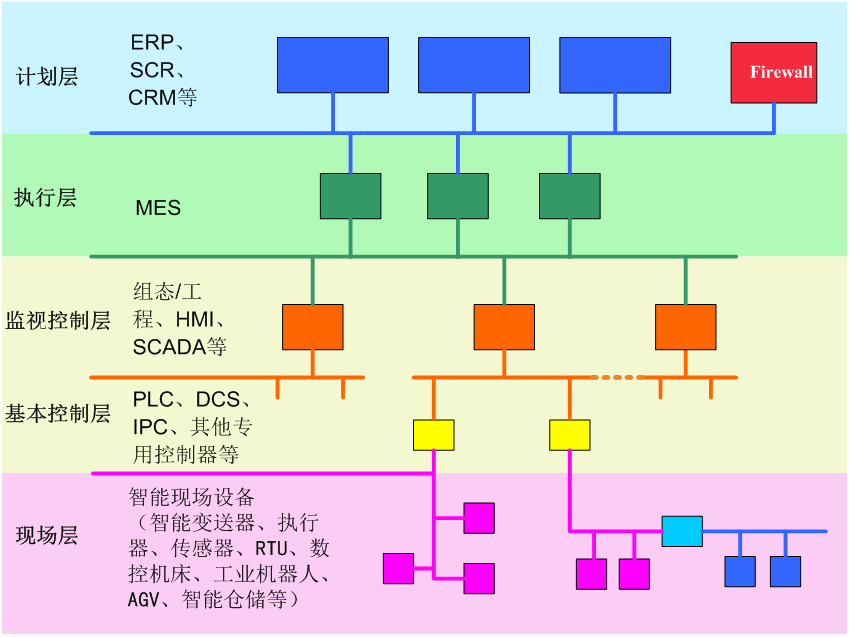

The primary task of intelligent manufacturing is information processing and optimization, and the interconnectivity of various networks within the factory/workshop is the foundation and prerequisite. Without interconnectivity and data acquisition and interaction, industrial clouds and industrial big data will be useless. The production management system (IT system) and intelligent equipment (automation system) in the intelligent factory/digital workshop are interconnected to form the enterprise's integrated network. According to the different functions performed, the enterprise's integrated network is divided into different layers, including the field layer, control layer, execution layer, and planning layer from bottom to top. Figure 2 shows a typical structure of an interconnected network for a smart factory/digital workshop that conforms to this hierarchical model. With the development of technology, this structure is becoming flatter to meet the needs of collaborative and efficient intelligent manufacturing.

The production management system (IT system) and intelligent equipment (automation system) in the intelligent factory/digital workshop are interconnected to form the enterprise's integrated network. According to the different functions performed, the enterprise's integrated network is divided into different layers, including the field layer, control layer, execution layer, and planning layer from bottom to top. Figure 2 shows a typical structure of an interconnected network for a smart factory/digital workshop that conforms to this hierarchical model. With the development of technology, this structure is becoming flatter to meet the needs of collaborative and efficient intelligent manufacturing.

Figure 2: Typical Network Structure of a Smart Factory/Digital Workshop

The functions defined for each layer of the interconnected network in a smart factory/digital workshop, and the allocation of various systems and equipment at different layers are as follows:

1) Planning Layer: Achieves enterprise-oriented business management, such as receiving orders, establishing basic production plans (such as raw material usage, delivery, transportation), determining inventory levels, ensuring that raw materials arrive at the correct production location in a timely manner, and remote maintenance management. Enterprise Resource Planning (ERP), Customer Relationship Management (CRM), and Supply Chain Relationship Management (SCM) software run at this layer.

2) Execution Layer: Achieves factory/workshop-oriented production management, such as maintenance records, detailed scheduling, and reliability assurance. Manufacturing Execution System (MES) runs at this layer.

3) Monitoring Layer: Achieves monitoring and control of the production manufacturing process. According to different functions, this layer can be further divided into:

Monitoring Layer: Includes visual data acquisition and monitoring (SCADA) systems, HMI (Human-Machine Interface), real-time database servers, etc. These systems are collectively referred to as the monitoring system;

Control Layer: Includes various programmable control devices, such as PLCs, DCSs, industrial computers (IPCs), and other special controllers. These devices are collectively referred to as control devices;

4) Field Level: Realizes sensing and execution oriented to the production manufacturing process, including various sensors, transducers, actuators, RTUs (Remote Terminal Units), barcodes, RFID, and manufacturing equipment such as CNC machine tools, industrial robots, AGVs (Automated Guided Vehicles), and intelligent warehousing. These devices are collectively referred to as field devices.

The network interconnection of factories/workshops essentially means realizing the transmission and use of information/data. Specifically, this includes: systems and devices physically distributed across different levels and types are connected via a network, and information/data is transmitted between different levels and devices; devices and systems can consistently parse the data type of the transmitted information/data and even understand its meaning. The former refers to networking, while the latter requires first defining a unified device protocol or device information model and expressing the specific characteristics (parameters or attributes) of the device through a computer-recognizable method (software or readable file), which is generally provided by the equipment manufacturer. In this way, when the production management system (such as ERP, MES, PDM) or monitoring system (such as SCADA) receives data from the field devices, it can parse the data type and its meaning.

5. What is end-to-end data flow?

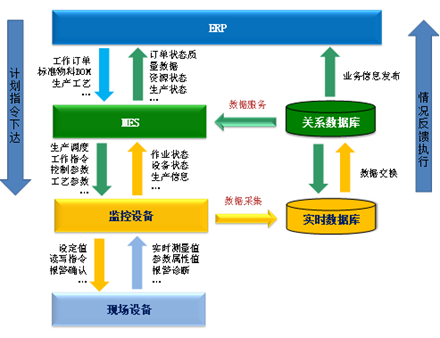

Intelligent manufacturing requires that network integration and interoperability at all levels break the disconnect between existing business processes and process control processes, so that systems distributed across various production and manufacturing processes are no longer "information islands." Data/information exchange requires end-to-end connectivity from the bottom field level up to the execution level and even the planning level network, allowing the factory/workshop to monitor the production status and equipment information in real-time and optimize and adjust production scheduling and resource allocation based on the information obtained. According to the intelligent factory/digital workshop network structure in Figure 2, the possible end-to-end data flow in the factory/workshop is shown in Figure 3.

Figure 3: End-to-End Data Flow in Intelligent Manufacturing

Specifically, this includes:

1) The data flow between field devices and control devices includes: exchanging input and output data, such as the setpoint (output data) sent by the control device to the field device, and the measured value (input data) sent by the field device to the control device; the control device reads and writes access to the parameters of the field device; the field device sends diagnostic information and alarm information to the control device;

2) The data flow between field devices and monitoring devices includes: the monitoring device collects input data from the field device; the monitoring device reads and writes access to the parameters of the field device; the field device sends diagnostic information and alarm information to the monitoring device;

3) The data flow between field devices and the MES/ERP system includes: the field device sends data related to production operation to the MES/ERP, such as quality data, inventory data, and equipment status; the MES/ERP sends job instructions and parameter configurations to the field device;

4) The data flow between control devices and monitoring devices includes: the monitoring device collects data needed for visualization from the control device; the monitoring device sends control and operation instructions and parameter settings to the control device; the control device sends diagnostic information and alarm information to the monitoring device;

5) The data flow between control devices and MES/ERP includes: the MES/ERP sends job instructions, parameter configurations, and recipe data to the control device; the control device sends data related to production operation to the MES/ERP, such as quality data, inventory data, and equipment status; the control device sends diagnostic information and alarm information to the MES/ERP;

6) The data flow between monitoring devices and MES/ERP includes: the MES/ERP sends job instructions, parameter configurations, and recipe data to the monitoring device; the monitoring device sends data related to production operation to the MES/ERP,

such as quality data, inventory data, and equipment status; the monitoring device sends diagnostic information and alarm information to the MES/ERP.

6. Current Status and Primary Tasks of China's Manufacturing Industry

The current status of China's manufacturing industry is "catching up on Industry 2.0, popularizing Industry 3.0, and demonstrating Industry 4.0." The meanings of Industry 2.0, 3.0, and 4.0 are as follows:

1) Industry 2.0 realizes "electrification and automation" production: using relays and electrical automation to control mechanical manufacturing equipment, but each production link and manufacturing equipment is an "information island." The production management system and the automation system information are not interconnected, and some enterprises have not yet used ERP or MES systems for production information management. Many small and medium-sized enterprises in China are at this stage;

2) Industry 3.0 realizes "information-based" production: widely applying electronic and information technology, significantly improving the degree of automation control in the manufacturing process. Using networked production manufacturing equipment based on PCs, PLCs, or single-chip microcomputers, manufacturing equipment has certain intelligent functions (such as identification and maintenance, diagnosis and alarm), using ERP and MES systems for production information management, initially realizing horizontal and vertical integration within the enterprise;

3) Industry 4.0 realizes "intelligent" production: using information and communication technology to highly interconnect all information infrastructure in the factory (including intelligent manufacturing equipment, operators, materials, semi-finished products, and finished products), using computer software tools to realize product digital simulation design and rapid physical "virtual" realization, using production management software to realize digital management of the entire product life cycle and the entire manufacturing process, using the Internet, cloud computing, and big data to realize value chain enterprise collaborative production, remote maintenance of products, intelligent services, etc., forming a new production model of highly flexible, large-scale personalized products and services.

China must develop Industry 2.0, 3.0, and 4.0 in parallel to achieve intelligent manufacturing. It is necessary to "catch up" in the transformation of traditional manufacturing and "add lessons" in green manufacturing and intelligent upgrading. For manufacturing enterprises, they should focus on completing the upgrading and transformation of traditional production equipment networking and intelligence, as well as the upgrading and transformation of digital manufacturing processes and production process information. For equipment suppliers and system integrators, they should accelerate the development and application of secure and controllable intelligent equipment and industrial software, and provide top-level design and full-system integration services for intelligent manufacturing.

5. Summary

It must be remembered that enterprises do not engage in "intelligent manufacturing" for the sake of "intelligent manufacturing." They should use intelligent, collaborative, green, and safe development as a breakthrough point, aiming for "two improvements and three reductions," and following the principles of long-term planning, gradual implementation, and key breakthroughs to gradually upgrade and transform the entire manufacturing industry.